The unique design and innovative technologies behind the OctoFrost IQF food processing equipment have an important impact on energy efficiency of the whole food processing cycle. Energy efficiency is an important aspect to be kept in mind by food processors. It translates in lower production costs, higher profitability and increased sustainability for the food processor.

Shorter cooking, blanching and chilling time

A shorter time for cooking, blanching and chilling is important not only for achieving a high quality product and avoiding overcooked / mushy product but also for energy efficiency. With the rainshower system and the impingement technology at the heart of the OctoFrost IF Cooker, IF Blancher and IF Chiller, heat transfer is significantly faster. Therefore, the cooking, blanching and chilling time is shorter. This translates in less energy consumption per kg of product and an increased profitability for the processor.

Low water consumption

Water consumption is only caused by water pick-up on the product which usually ranges between 5% and 10% of the production capacity (e.g. for a 2000 kg/h production, water consumption would amount 140 liters per hour). Because of the recirculation system, the OctoFrost™ IF Blancher, IF Cooker and IF Chiller use up to 90% less water than other water blanching and chilling systems.

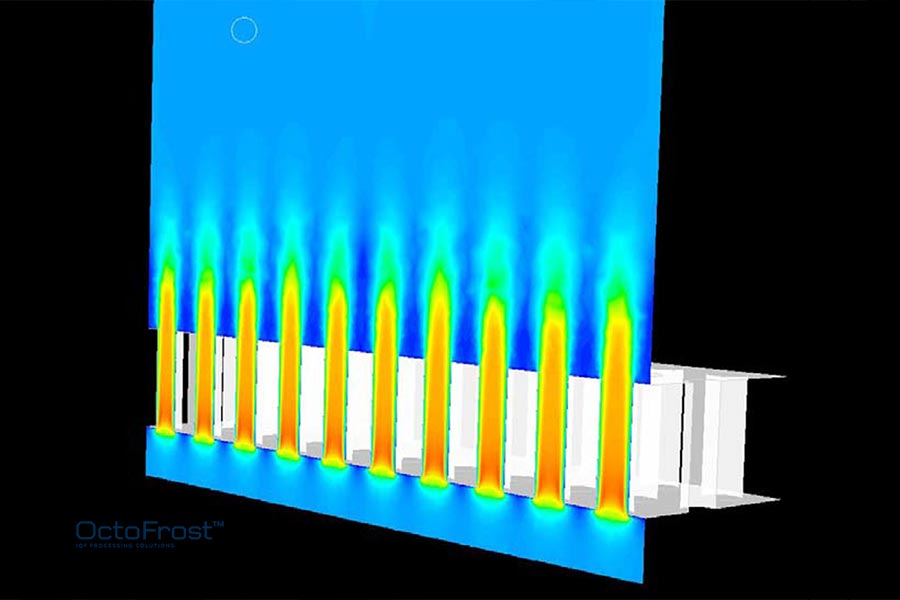

Energy efficient water heating

The water in the OctoFrost IF Blancher and IF Cooker is heated by means of direct steam injection, which is absorbed completely into the water. A high volume of recirculated water is used to shower the product that results in a very low temperature-drop when exiting the blancher or cooker (ΔT is max. 3° C). Therefore, very little steam is needed to reheat the water, translating in maximum energy efficiency. In comparison to traditional steam blanching technologies, a 30% to 40% reduction in steam consumption can be achieved because there is no escape of steam when reheating the water.

Energy efficient IQF freezer fans

The OctoFrost tunnel Freezer uses axial vane fans, each of which can run at different speeds. There is no need for more than 75% – 85% fan speed and for some light products, the speed does not exceed 30%, which means considerable energy savings. The OctoFrost™ custom-made axial vane fans have been carefully designed to work together with the OctoFrost™ Freezer body and bedplate. Also, by investing in a smaller compressor, the OctoFrost IQF Freezer has less heat to cool down and thus, the fans consume even less energy.

The optimal thickness of the OctoFrost™ bedplates and the bedplates holes’ configuration create a higher pressure drop and avoid dead zones, making it possible to achieve optimal airflow with lower fan speed, depending on the product characteristics. This translates into less energy consumption with improved freezing result.

OctoFrost fan speed needed for specific products:

- 75% – 85% Strawberries, beans, blueberries, carrots

- 60% – 75% Raspberries, diced meat, shrimp, rice, mango, pasta

- 40% – 60% Chives, mozzarella, cheese

- 30% Herbs

No need for floor heating

The OctoFrost™ Freezer has an elevated housing, resting on its own supporting feet. This enables the air to circulate under the freezer while avoiding cold transfer to the floor and, unlike other IQF freezers, make floor heating unnecessary.

Learn more about the IQF FreezerEfficient freezer insulation

The “sandwich type” insulation walls together with the smaller size of the OctoFrost™ Freezer lead to less cold escaping through the walls and ultimately greater energy saving.

Learn more about the IQF Freezer