Benefits of Octofrost vegetable processing equipment

When processing IQF frozen vegetables – such as broccoli, carrots, peas, corn, edamame, leafy vegetables like spinach and herbs or even whole asparagus or artichoke – OctoFrost offers optimal machinery designed to achieve the best final product while ensuring energy efficient processing, food safety, and high yield for the processor.

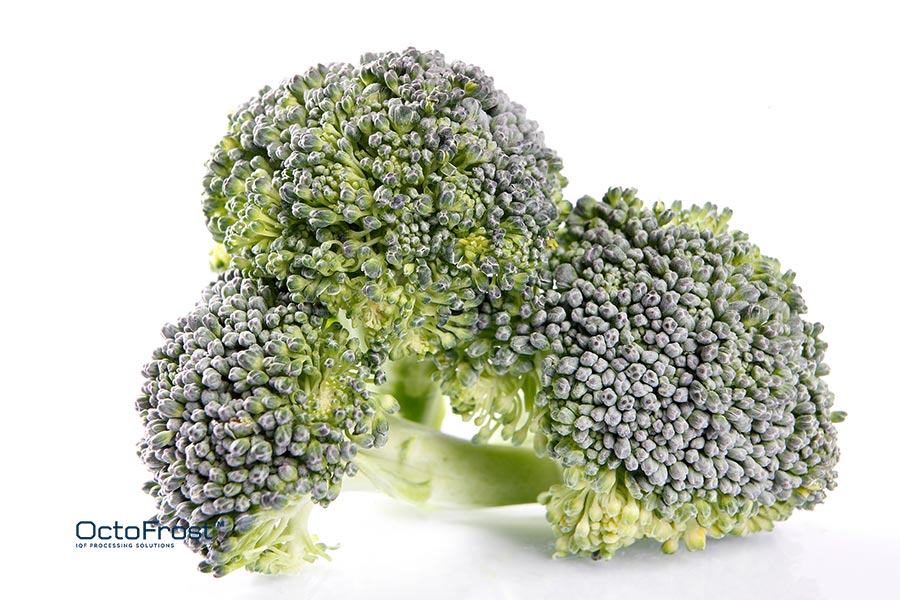

Natural Appearance

Full control over the blanching temperature in the IF Blancher is important for keeping the natural color of vegetables and a crisp bite. Further on, with efficient chilling below 5°C in the OctoFrost IF Chiller, quick crust-freezing is achieved in the OctoFrost Tunnel Freezer. A low infeed product temperature is crucial for a high quality IQF vegetable.

Energy Efficiency

The rainshower and cross-flow systems, which are at the heart of the IF Blancher and Chiller, help achieve the quickest heat transfer while the recirculation system optimizes water consumption. The adjustable fan speed of the OctoFrost freezer translates in significant energy savings.

High Yield

Quick and efficient blanching and chilling, together with the unique aerodynamics of the OctoFrost Freezer, result into less snow formation when compared to other technologies, which means minimum dehydration and higher yield for the processor.

Food Safety

All OctoFrost equipment has easy-to-clean design for ensuring optimal food safety. Every part of the blancher and chiller which comes in contact with the blanching water can be cleaned by CIP (Cleaning-In-Place). The free-standing body, lack of joints and exchangeable bedplates of the OctoFrost freezer contribute even further to food safety for IQF vegetable processors.

Technology for IQF vegetable processing machinery

Blanching Technology for IQF frozen vegetables

The OctoFrost IF Blancher has the unique benefit of precise temperature control for ensuring the best product quality. This innovative solution brings true value to vegetable processors:

- Weighing belt for an even infeed into the blancher.

- Flexibility of different temperature zones to avoid over-blanching.

- Energy efficient steam injection to heat the blanching water.

- Cross-flow water circulation for smart water consumption.

Chilling Technology

The IF Chiller built by OctoFrost is based on impingement flash (IF) technology that achieves the quickest and most efficient heat transfer with its rainshower system. This innovative solution brings true value to vegetable processors and allows them to produce high quality IQF products:

- Significantly faster heat transfer due to the impingement rainshower system.

- Quick chilling with high flow of recirculated ice-cold water, which improves yield and product quality.

- System temperature below 6°C for optimal food safety.

- Low product temperature achieved for a premium IQF final product.

IQF Technology

The IQF technology, developed by Octofrost, has a number of unique features that bring real value to vegetable processors all around the world:

- Adjustable airflow for quick crust-freezing in the first freezing zone which translates into no lump formation, good product separation and energy efficiency.

- Exchangeable OctoFrost bedplates for gentle handling of soft products and quick and easy cleaning between different batches.

- Overall easy-to-clean design for optimal food safety.

These are a just a few of the key benefits OctoFrost customers enjoy from this unique IQF tunnel Freezer. Learn more by clicking on the video above.