Benefits of OctoFrost IQF Tunnel Freezer

Natural Appearance

The optimal airflow and the unique exchangeable bedplates ensure gentle handling and good separation of the products in all stages of the freezing process, even with extremely sensitive products. The end result is a premium product with a preserved natural appearance.

Energy Efficiency

The frequency converters installed on each fan allow the food processor to adjust the fan speed based on the type of product to be processed. This setup requires less refrigeration in order to cool down the heat produced by the fans, which means that using the OctoFrost IQF technology the energy savings can reach up to 30%.

High Yield

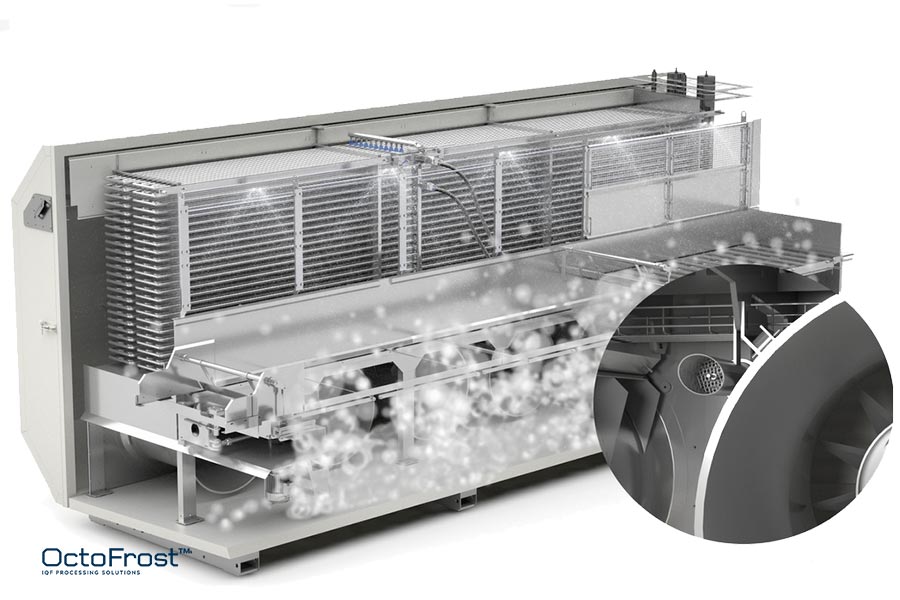

The optimal aerodynamics achieved by the IQF tunnel freezer decreases the dehydration of the products and prevents snow formation in the freezer. Lower product dehydration translates into higher profitability for the food processor, because their products will maintain their natural volume, shape, and color. Thus, they can be sold at a premium price.

Food Safety

The OctoFrost IQF tunnel freezer is designed as an easily accessible monoblock uni, with rounded corners, sloping surfaces, and a Clean-in-Place (CIP) system. The bedplates can be exchanged with ease for efficient cleaning, which minimizes the risk of cross-contamination between different product batches.

THE UNIQUE AERODYNAMICS OF THE IQF TUNNEL

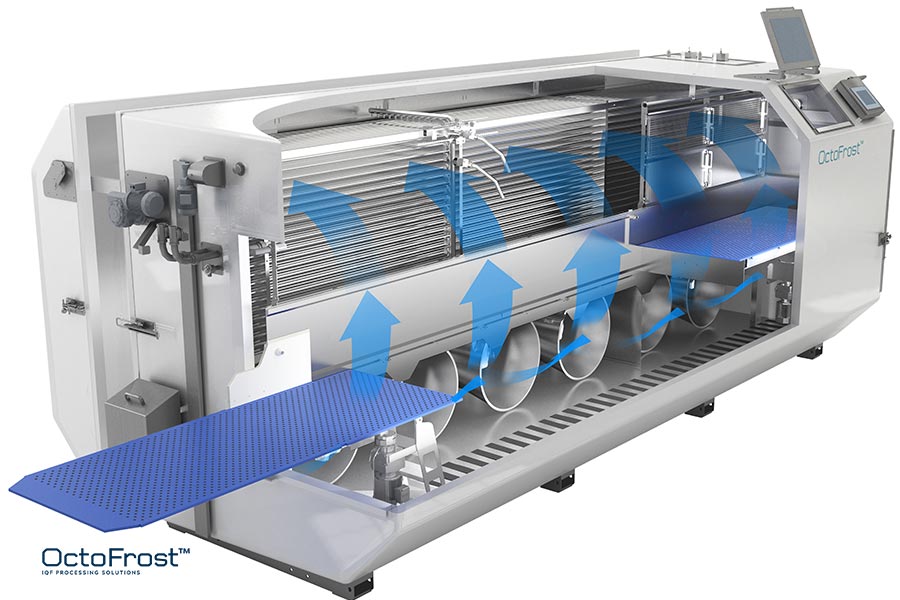

Because of its features, the OctoFrost IQF tunnel freezer is known for creating unique aerodynamics. The bedplate configuration, overall freezer design and shape, and the high-performance fans with frequency converters contribute to a high-quality IQF result.

ADJUSTABLE AIRFLOW FOR A PREMIUM PRODUCT

With high-performance fans fitted with frequency converters, the airflow can be adjusted for different product types, achieving energy efficiency and optimal performance. Because the fan speed does not need to exceed 75% - 85% - for some light products the speed does not exceed 30% - the OctoFrost IQF tunnel freezer allows processors to save considerable energy. For some light products, the speed does not exceed 30%. The OctoFrost custom-made axial vane fans have been carefully designed to work together with the freezer body and bedplates. Lastly, using a smaller compressor, the OctoFrost IQF tunnel freezer has less heat to cool down and thus the fans consume even less energy.

HYGIENIC DESIGN

The OctoFrost™ IQF tunnel freezer is designed as an easily accessible free-standing monoblock unit with rounded corners and sloping surfaces which allows thorough cleaning under the freezer as well. The bedplates, which can be easily exchanged and cleaned outside the freezer, decrease downtime without compromising food safety. In combination with an effective Clean-In-Place (CIP) system, it helps processors maintain high food safety standards.

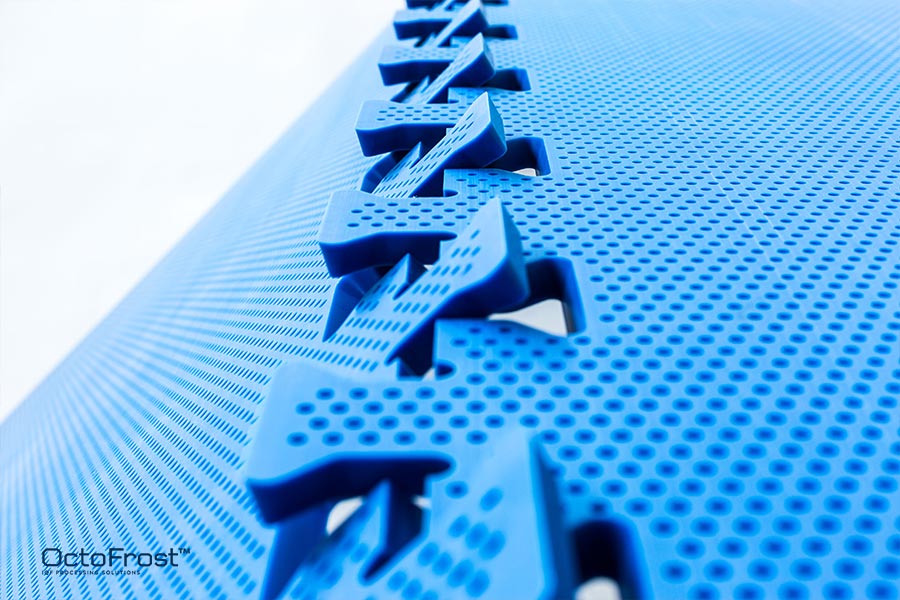

EXCHANGEABLE BEDPLATES

The OctoFrost IQF tunnel freezer is fitted with exchangeable bedplates instead of a belt. The OctoFrost bedplates are considered one of the most innovative improvements to the hygienic design of freezing tunnels. With a puzzle-like connection between the pieces of bedplates, these can be easily removed and washed outside the tunnel freezer:

- This gives the flexibility of quick product change without the risk of cross-contamination between different product batches.

- No downtime for cleaning the bedplates as a new and clean set can be used immediately after removing the used one.

- Easy and efficient cleaning outside the freezer for food safety.

The optimal thickness of the OctoFrost™ bedplates and the bedplate holes’ configuration create a higher pressure drop and avoid dead zones, making it possible to achieve optimal airflow with lower fan speed depending on the product characteristics. This translates into less energy consumption with the improved freezing results.

EASY INSTALLATION

The OctoFrost ™ IQF tunnel freezer is a compact and highly effective freezer with a small footprint. It is the smallest freezer on the market – usually up to 50% smaller than any other freezer for the same production capacity. It is also a ready-built machine, which can be easily transported on a regular truck or container ship.

OctoFrost tunnel freezer comes thoroughly tested from the factory and is ready for operation within 2-3 days after arrival, thus normal food production in the factory can continue during installation. Because of the compact design of the freezer that rests on its own supporting feet, there is no need for floor preparation, foundation, or other fixed installations. Also, the air can circulate under the freezer to avoid accumulation of cold on the floor.

Because of its optimal size, the Octofrost IQF tunnel freezer can be moved into the production hall by merely using a forklift without any big arrangements. The installation process of an IQF tunnel Freezer is vital for IQF processors. A simple process can save a lot of time and hassle in logistics, operations, and production in the factory.

Products for IQF FREEZER

Equipment capacities

OctoFrost offers a capacity range of 500 to 15,000 kg/h for the OctoFrost IQF Freezer.