Benefits of OctoFrost Shrimp Processing Equipment

Premium Quality Shrimp

The OctoFrost Shrimp Cooker ensures minimum curling, right shrimp color and texture, and preserves taste and flavor of the shrimps. Optimal product quality and yield is guaranteed with quick and efficient cooking.

High Yield

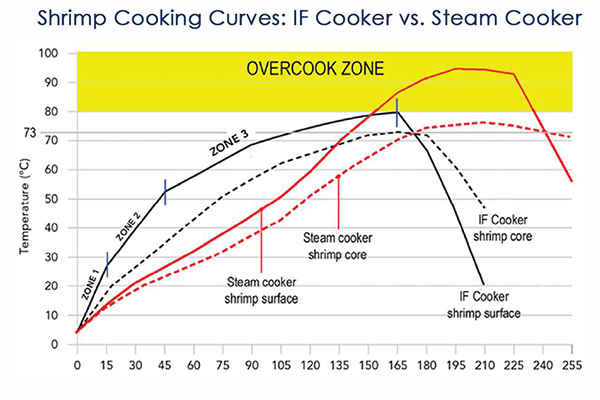

Temperature of the shrimp’s surface remains below 80°C, which results in at least 1% yield gain compared to forced convection steam cooking. In comparison to traditional steam cookers, the yield gain can reach 9%.

Energy Efficiency

The water in the OctoFrost™ IF Cooker is heated by means of direct steam injection, which is absorbed completely into the water. A high volume of recirculated water is used which has a very low temperature-drop when exiting the cooker (ΔT – max. 3° C), therefore very little steam is needed to reheat the water. A 30% to 40% reduction in steam consumption can be achieved compared to traditional steam cooking technologies because there is no escape of steam when reheating the water.

Food Safety

Every part of the cooker that comes in contact with the blanching water can be cleaned by Clean-In-Place (CIP) system. All piping, Aisi 316 stainless steel, is backing-gas welded, ensuring the highest hygienic standard possible. The cooking process guarantees 100% food safety regarding homogeneous cooking, with no ‘undercooked’ meat or grey spots, even with small-sized peeled and un-deveined shrimp (PUD).

The OctoFrost™ IF Cooker, with its first unit installed in Thailand in 2013, is the most technologically advanced shrimp cooker in the industry.

Temperature control in the shrimp cooking machine

Accurate temperature control is crucial for high-quality shrimp. Traditional or forced convection steam cookers cannot give the operator as precise control over the cooking temperatures as the IF Cooker.

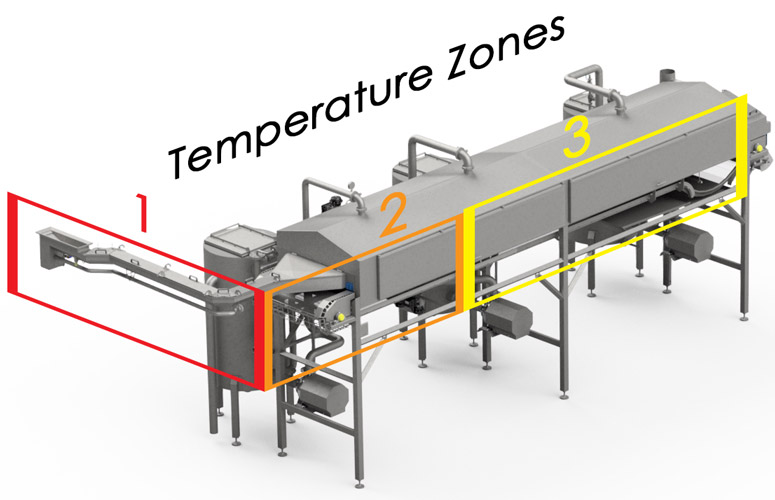

The 3 temperature zones of the OctoFrost™ IF Cooker provide optimal flexibility and control of the cooking process. The set temperatures can be stored in a recipe inside the touch-panel for every single batch of shrimp. The OctoFrost™ IF Cooker accurately controls the temperature in each zone.

Control is key when cooking shrimp.

Temperature zones

When cooking shrimp, it is important to quickly heat the product during the first few seconds of the cooking process, especially the surface of the shrimp, to prevent melanosis (black tail, legs). The IF Cooker can accurately adjust the temperature in each of the 3 or 4 cooking zones.

The 3 temperature zones system allows the user to start with a higher temperature in zone 1 while reducing it in zones 2 and 3. This creates a “flat belly” temperature curve, allowing the heat to travel to the core of the product without overcooking the surface (see graph below).

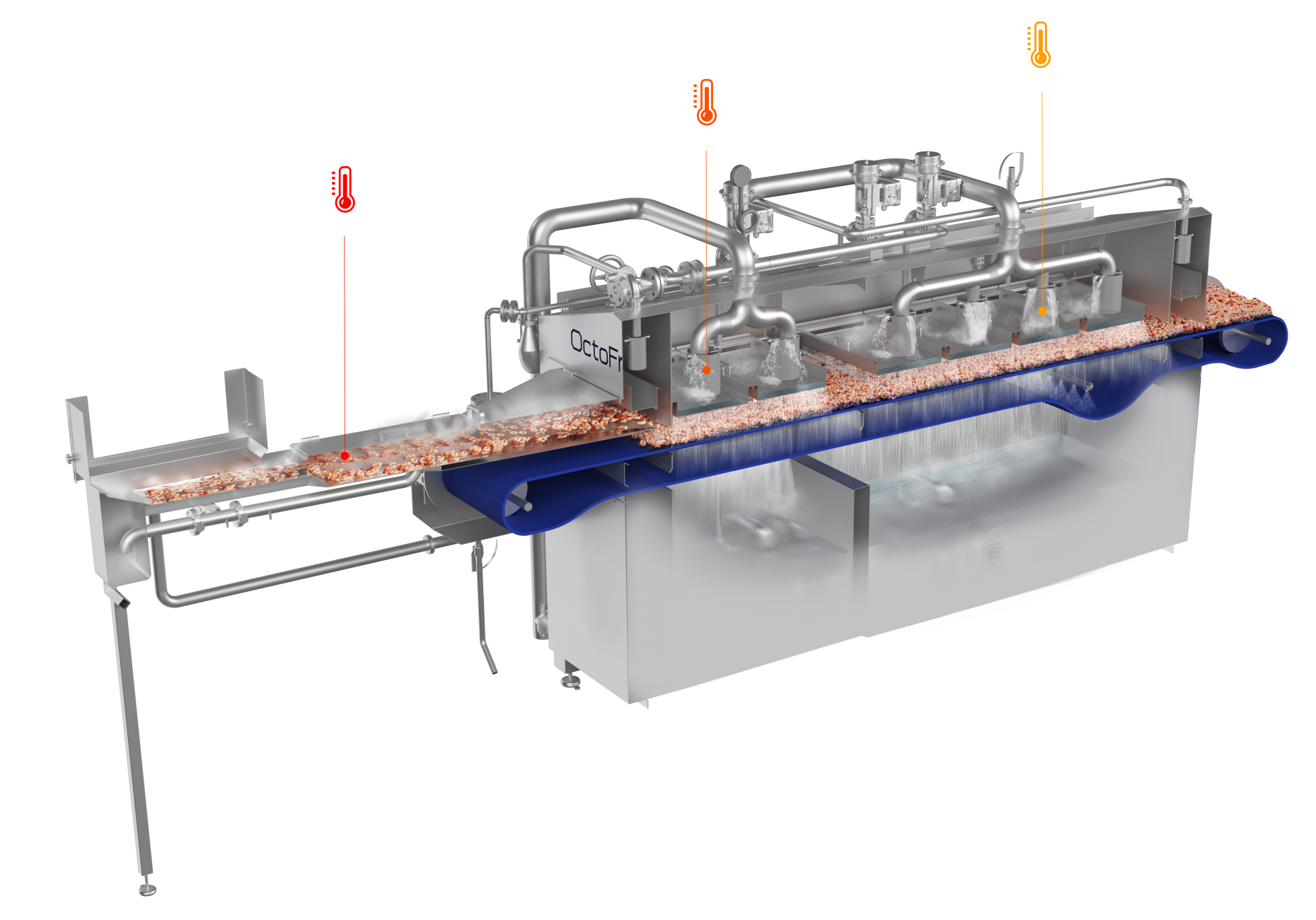

Rainshower System in Shrimp Processing Equipment

The rainshower system guarantees quickest heat transfer, allowing accurate temperature control within 0.2°C of the set temperatures.

The water falls gently over the product by means of gravitation only, therefore the product quality is not compromised.

Additionally, the rainshower system has a product cleaning function.

Products for IQF Cooker

Equipment capacities

OctoFrost offers a capacity range of 1,000 to 15,000 kg/h for the OctoFrost IF Blancher.