Benefits of the OctoFrost Blancher

Natural Appearance

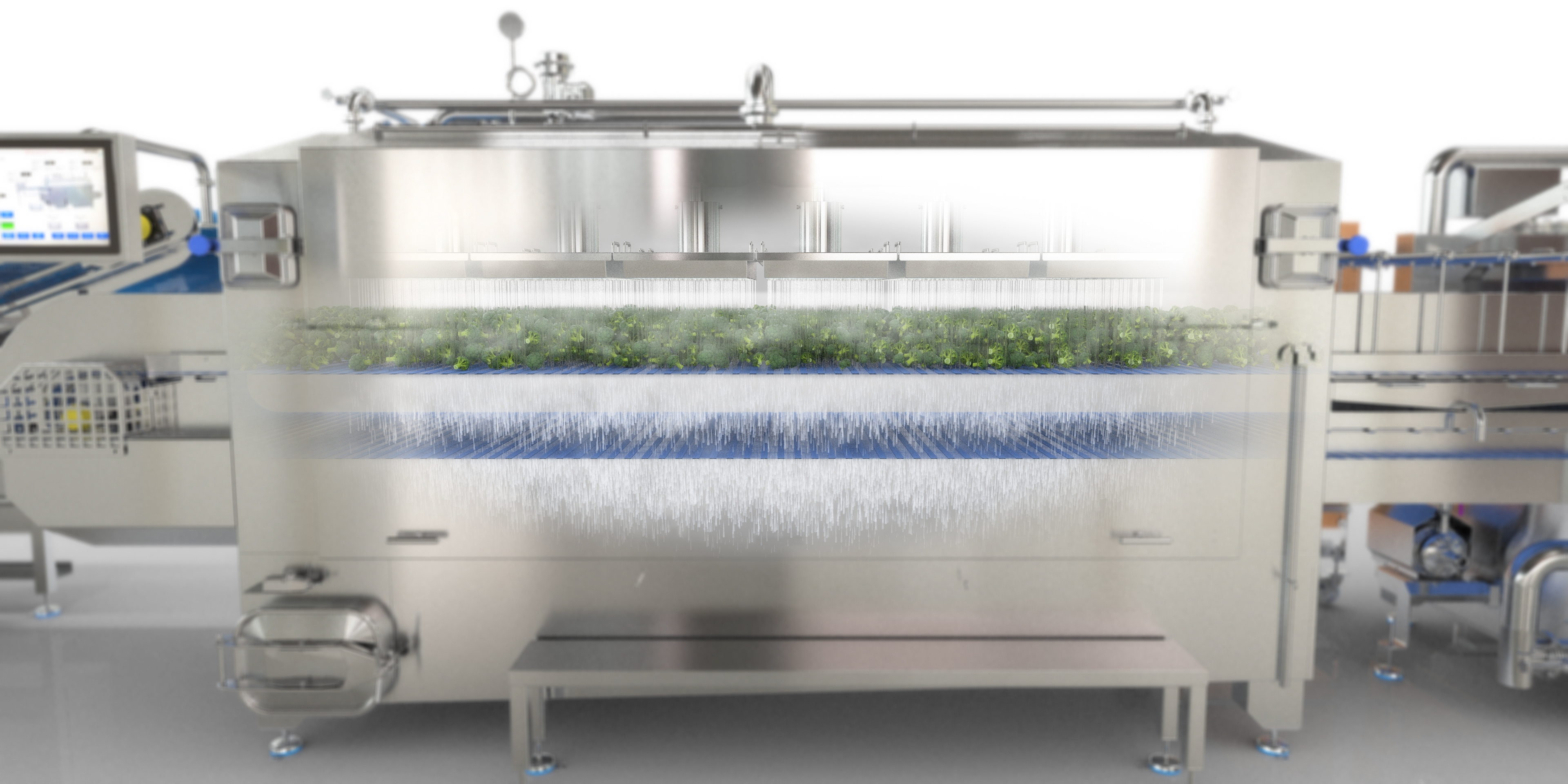

Full control over the blanching temperature and time preserves the natural color and texture of the blanched products. This is possible due to the rainshower technology and the cross-flow water system in the OctoFrost blanching machine.

Energy Efficiency

The water in the blancher is heated by means of direct steam injection, which is absorbed completely into the water. The recirculation system requires very little steam to reheat the water, translating in maximum energy efficiency. 30% to 40% reduction in steam consumption can be achieved compared to traditional steam blanching technologies because there is no escape of steam when reheating the water.

High Yield

Blanching temperature control is a key element to preserve high production and high yield. With the OctoFrost IF Blancher, the blanched products maintain their firmness, helping the processor to achieve premium quality of the products.

Food Safety

The IF Blancher has been designed to exceed all international regulations on food safety and hygiene. Every part of the blancher that comes in contact with the blanching water is thoroughly cleaned by the Clean-In-Place (CIP) system.

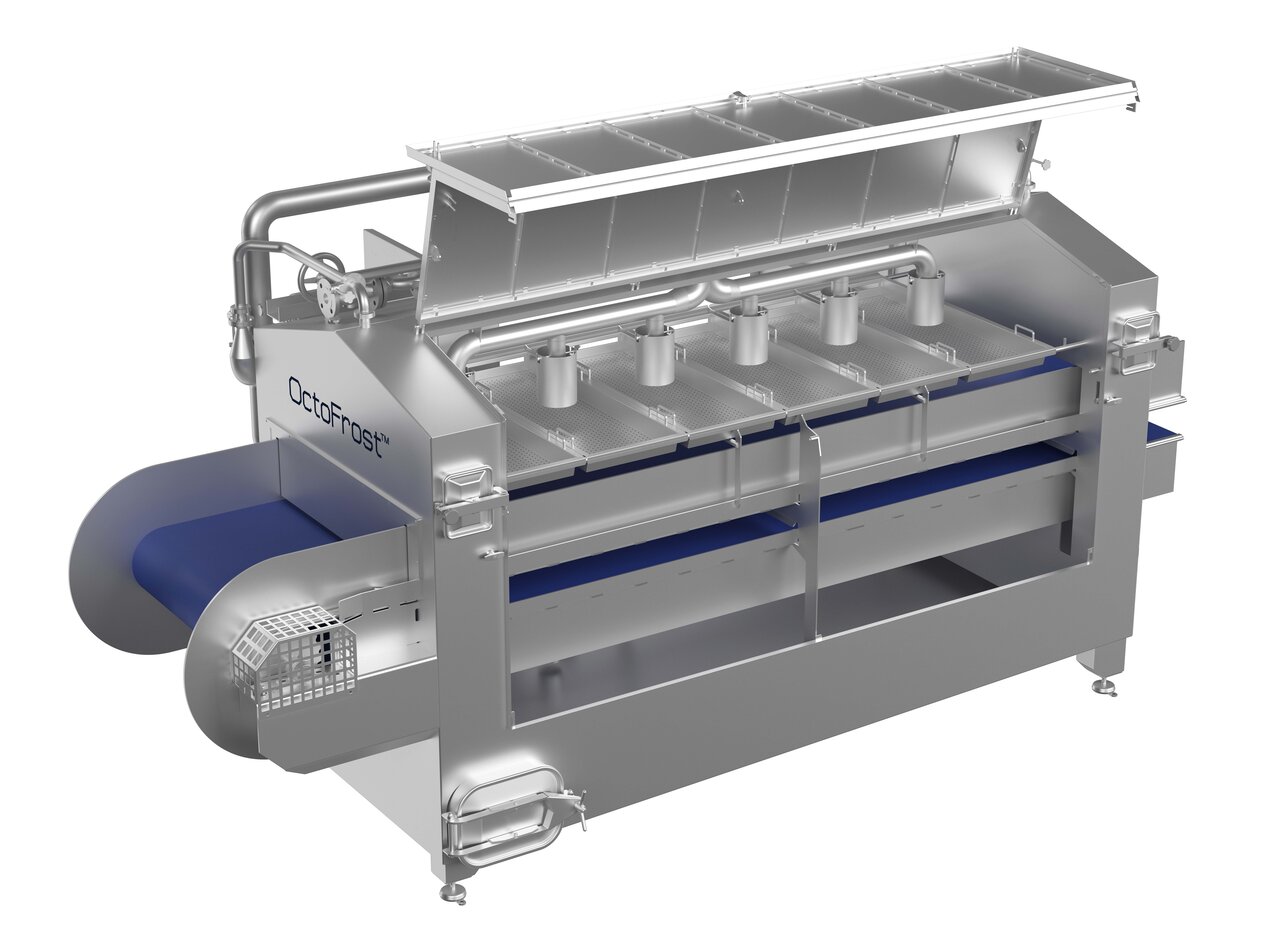

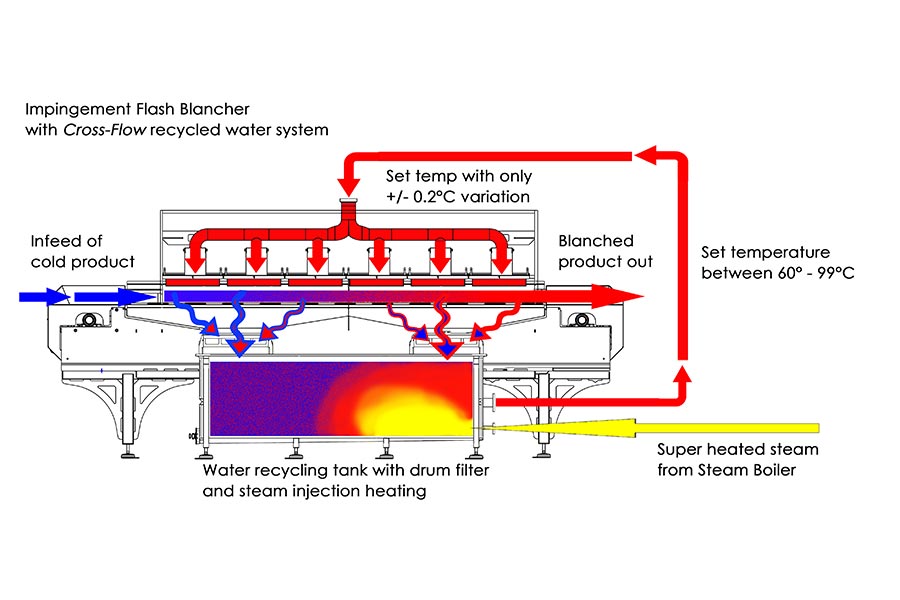

FULL TEMPERATURE CONTROL OF THE BLANCHING EQUIPMENT

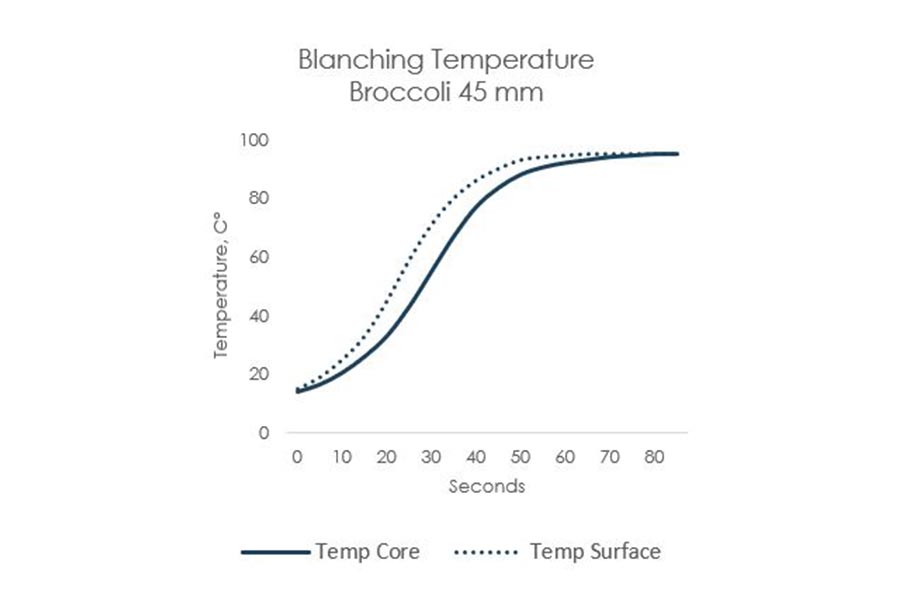

With the Impingement Flash technology, the blanching time is reduced to a minimum, preventing over-blanching and reducing time and energy consumption. The user of the OctoFrost™ IF Blancher has absolute control over the blanching termperature based on exposure time.

Optionally, the OctoFrost™ IF Blancher can be fitted with a second temperature zone to reduce temperature in the final blanching stage for delicate products that are prone to over-blanching.

OCTOFROST™ CROSS-FLOW WATER SYSTEM

The unique cross-flow water system uses high volume of filtered and recirculated water that showers over and through the product, and immediately exits the blancher. The water then re-enters the heating tank. Due to the high volume of water used, the temperature drop (delta T°) is maximum 3° C. The water flowing through the OctoFrost IF Blancher has the correct set temperature in every part of the blancher.

Rainshower System

The rainshower system guarantees quickest heat transfer, allowing accurate temperature control within 0.2°C of the set temperatures. The water falls gently over the product by means of gravitation only, therefore product quality is not compromised. Additionally, the rainshower system serves a product cleaning function.

KEY BENEFITS OF THE IF BLANCHER

- Flexibility of different temperature zones to avoid over-blanching.

- Energy efficient steam injection into the blanching water.

- Cross-flow water circulation.

- Faster heat transfer due to the impingement rainshower system.

- High volume of recirculated water over the product.

- CIP system in place.

- Control over blanching time and temperature (different sections of the blancher can be turned on or off, with the additional flexibility of speeding-up or speeding-down the belt).

Products for OctoFrost Blancher

Equipment capacities

OctoFrost offers a capacity range of 1,000 to 15,000 kg/h for the OctoFrost Blancher.