Food Safety has always been one of the main priorities when designing and building the OctoFrost processing equipment. The thought-through design of the machines meets and surpasses all international standards for food processing equipment.

It is important to note that food safety is not only limited to an easy-to-clean design but also to a cooked through protein product, which is safe for consumption. All these aspects are taken very seriously at OctoFrost and the equipment has a number of features to ensure an overall food safe product and production process.

Easy-to-Clean Equipment Design

The OctoFrost equipment is designed to surpass all international hygiene standards and requirements.

OctoFrost IF Cooker, IF Blancher and IF Chiller all feature a CIP (Cleaning-In-Place) system, which covers the cleaning of every part of the machine that comes into contact with the blanching or chilling water.

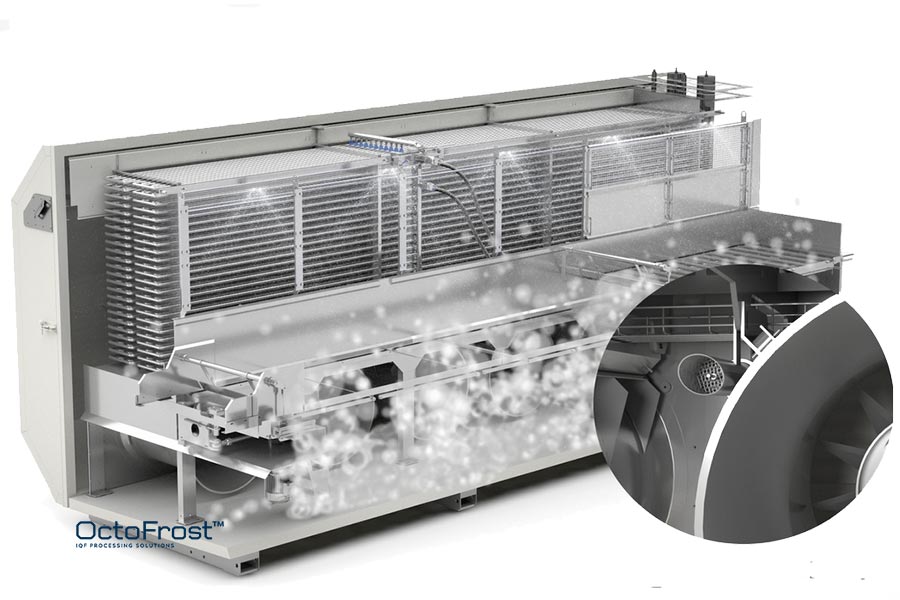

OctoFrost™ IQF tunnel Freezer is designed as an easily accessible hermetic unit with rounded corners and sloping surfaces for thorough and efficient cleaning. Easily exchangeable and cleaned outside the freezer, the bedplates decrease downtime without compromising food safety. In combination with an effective Clean In Place (CIP) system, it helps processors maintain high food safety standards. The free-standing monoblock housing allows easy cleaning under the freezer as well.

Homogeneously Cooked Shrimp Core

Food safety regulations require a fully cooked shrimp core of 73°C. This should be reached without overcooking the shrimp to ensure highest product quality and lowest yield loss. The OctoFrost™ IF Cooker guarantees 100% food safety regarding homogeneous cooking which means no ‘undercooked’ meat or grey spots:

- Accurate temperature and time control in all 3 temperature zones for high-quality shrimp.

- Cross-flow water system for shorter but more efficient cooking time.

- Automatic Rejection Chute which discards undercooked shrimp into a rejection bin, preventing it from entering the chilling and freezing equipment in case of an unexpected temperature drop, caused by a steam boiler failure for example.

Learn more about the IF Cooker

Easy-to-Clean Belts

The OctoFrost IF Chiller and IF Blancher are both featuring suspended belts without support frame or wear and tear parts. This considerably improves the quality of the cleaning cycle and saves precious time for the processor without compromising food safety.

Low Chilling Water Temperature

The water in the whole IF Chiller, including the Plate Heat Exchanger (PHE) and water filter, will always remain below the critical 6°C to guarantee food safety. This means that the chiller can run non-stop without the need for changing water until the end of the production day.

Learn more about the IF Chiller

Stainless Steel Piping

The IF Blancher, IF Cooker and IF Chiller are fitted with piping that is Aisi 316 stainless steel and backing-gas welded. This ensures food safety even with brine solutions being used in processing.

Safe Product Change

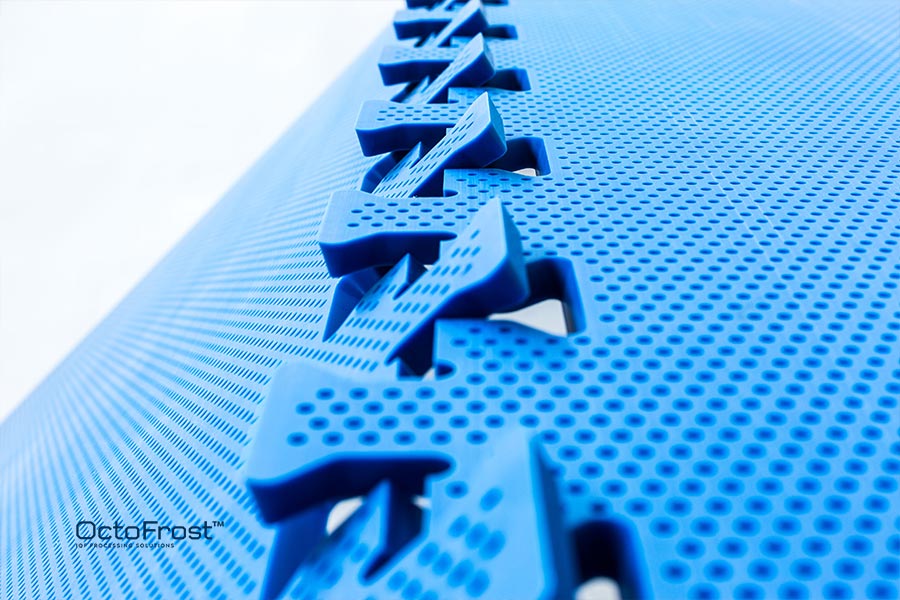

The OctoFrost IQF Freezer is fitted with exchangeable bedplates instead of a belt. The OctoFrost bedplates are considered one of the most innovative improvements to the hygienic design of freezing tunnels. With a puzzle-like connection between the pieces of bedplates, these can be easily removed and washed outside the freezer:

- This gives the flexibility of quick product change without the risk of cross-contamination between different product batches.

- No down-time for cleaning the bedplates as a new and clean set can be used immediately after removing the used one.

- Easy and efficient cleaning outside the freezer for utmost food safety.

Learn more about the IQF Freezer