Traders from all around the world confirm that they are eager to pay 5% to 30% more for premium quality IQF products.

OctoFrost Processing Solutions have been designed and built while considering the importance of a naturally-looking IQF product.

A natural color, a good texture, and appetizing flavour – all these product characteristics have been kept in mind when developing the OctoFrost IQF processing technology.

Premium product sells at premium price

Achieving overall efficient processing with each of the OctoFrost machines, the final end result is a premium IQF product which is usually sold at premium prices. The efficiency of each equipment separately contributes significantly to the ability of the processor to offer a high-quality IQF product. Due to no over-cooking / over-blanching and efficient chilling and high-quality IQF freezing, there is no lump, coral formation, product fines, or damage. This means a premium product, less waste, and overall higher yield for the food processor.

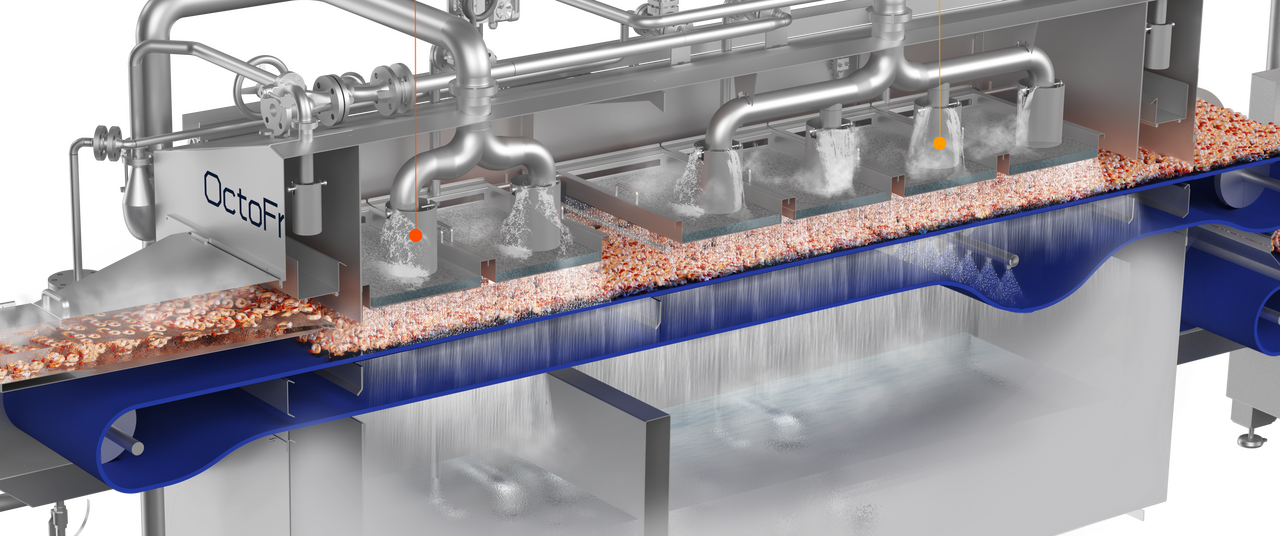

Evenly-Cooked Seafood Products

The 3 temperature zones of the IF Cooker and the cross-flow water system help the processor to achieve full temperature-control of the cooking process. This contributes to high-quality cooked seafood products:

- Homogeneously cooked product

- No excessive curling in shrimp caused by over-cooking

- No grey spots or under-cooked meat

- Right shrimp color and texture

- Preserved taste and flavor

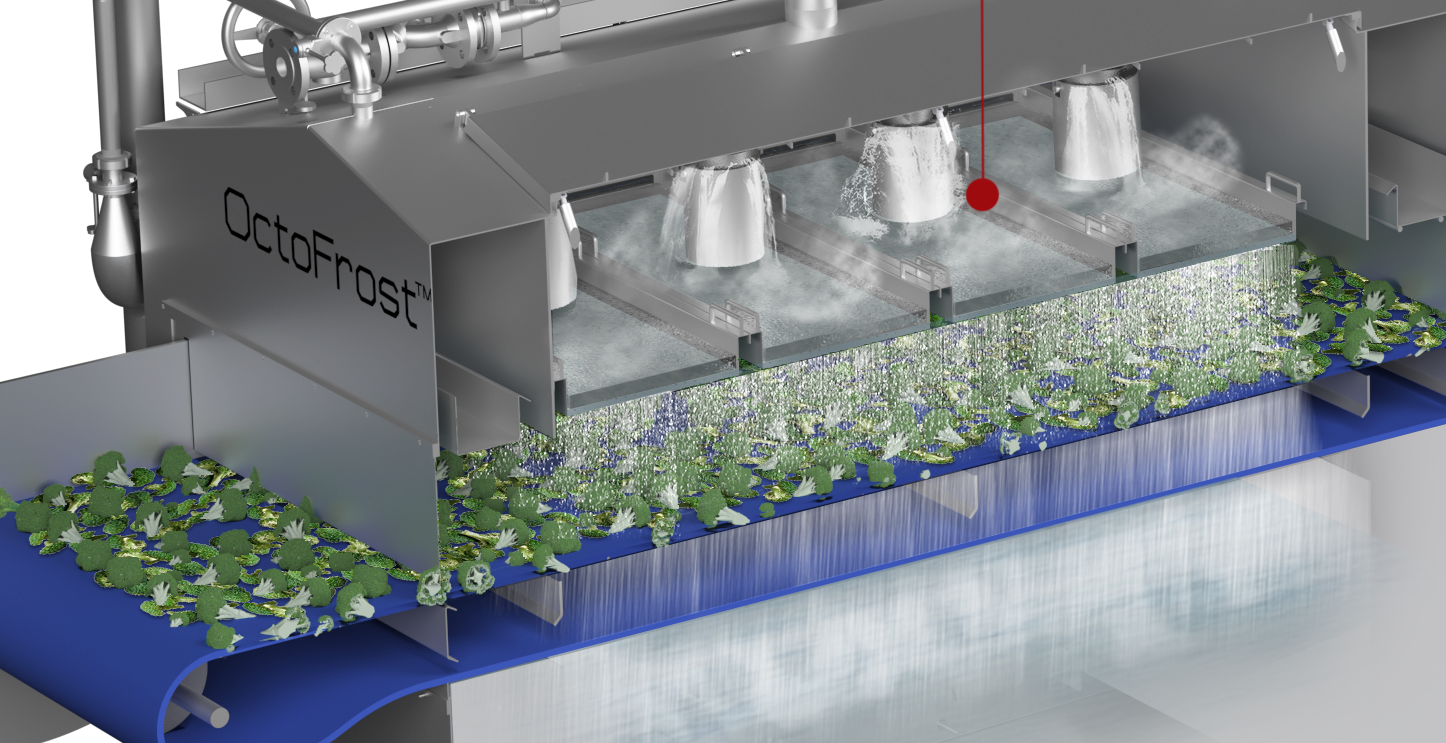

Blanched Products with a Natural Appearance

With the cross-flow water system of the OctoFrost™ IF Blancher, the processor has complete control over the blanching temperatures – a crucial precondition for a premium-quality blanched product:

- No over-blanching

- Natural product color and crisp bite

- Preserved taste and nutrients

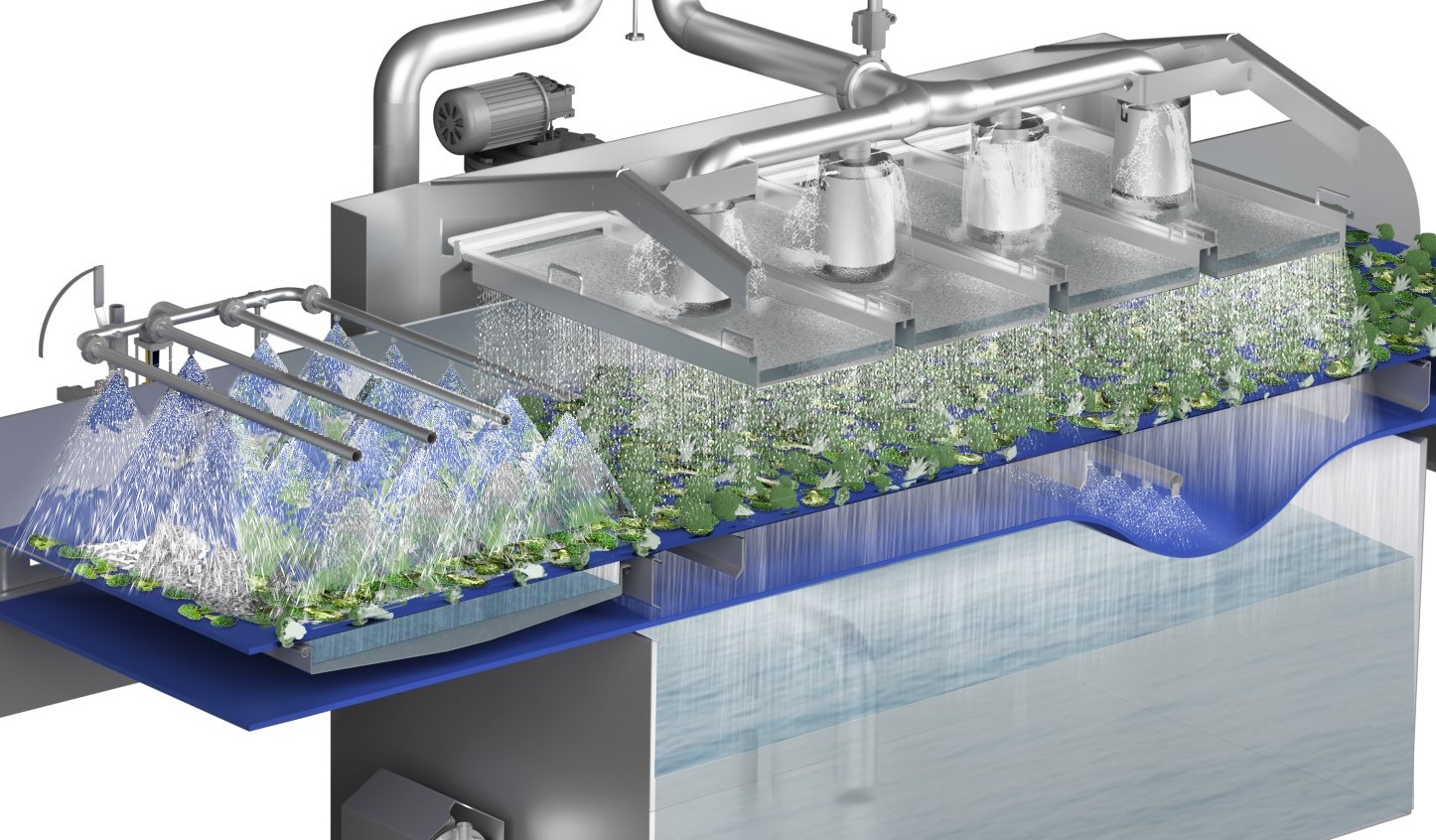

Efficient Chilling for Good Freezing Result

The product separation in the IQF Freezer starts with a low infeed temperature of the product. With the OctoFrost IF Chiller, the processor can achieve a well-chilled product with a core temperature of 5°C or less.

After blanching or cooking, the product will gently fall into the ice-cold water, which will immediately stop the blanching or cooking process, while preserving a high yield.

This will contribute to a better freezing result and a good product separation in the freezer.

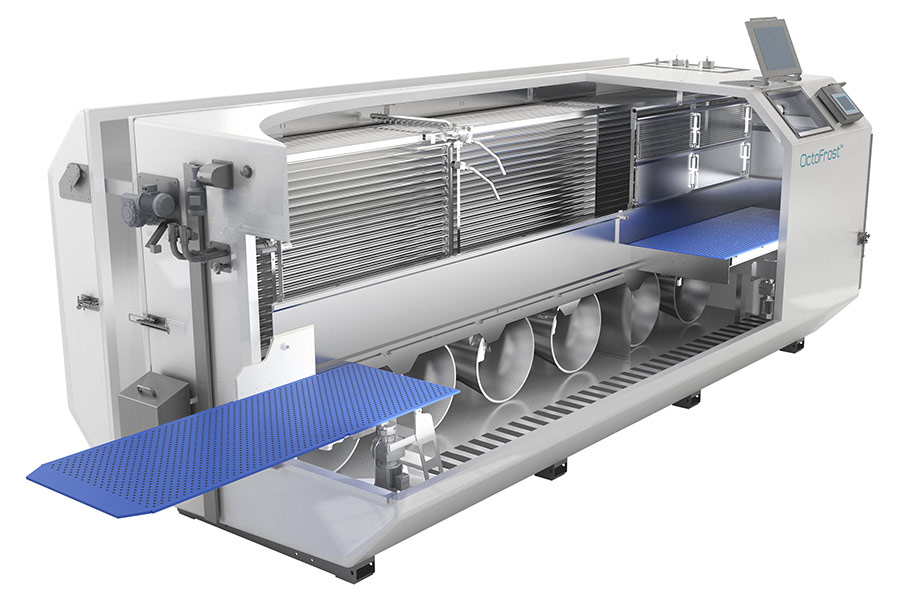

Good Separation During IQF Freezing

Sticky and soft products – such as diced tropical fruits, seafood products, cheese or meat products – can easily form lumps and “corals” in the freezing process.

However, the well-adjusted airflow in the first freezing zone of the OctoFrost IQF Freezer separates each piece of product and creates a crust around the product’s surface, locking in all the moisture for a natural-looking, well-preserved product.

In addition, the extra features such as bed vibrator, pulsator or wave plate help in efficiently separating each piece of product.

PREMIUM IQF PRODUCT SELLS AT PREMIUM PRICE

The unique fluidization technology of the OctoFrost™ IQF tunnel preserves the shape of the most fragile and brittle products such as raspberries, shrimp with antennas, soft mango dices, etc. As the OctoFrost fans’ speed can be adjusted, the optimal airflow will gently transport the product towards outfeed, efficiently separating each piece and without causing any damage. In addition, the unique OctoFrost bedplates ensure that there are no marks on the surface of the product, achieving the highest quality of the end IQF product.